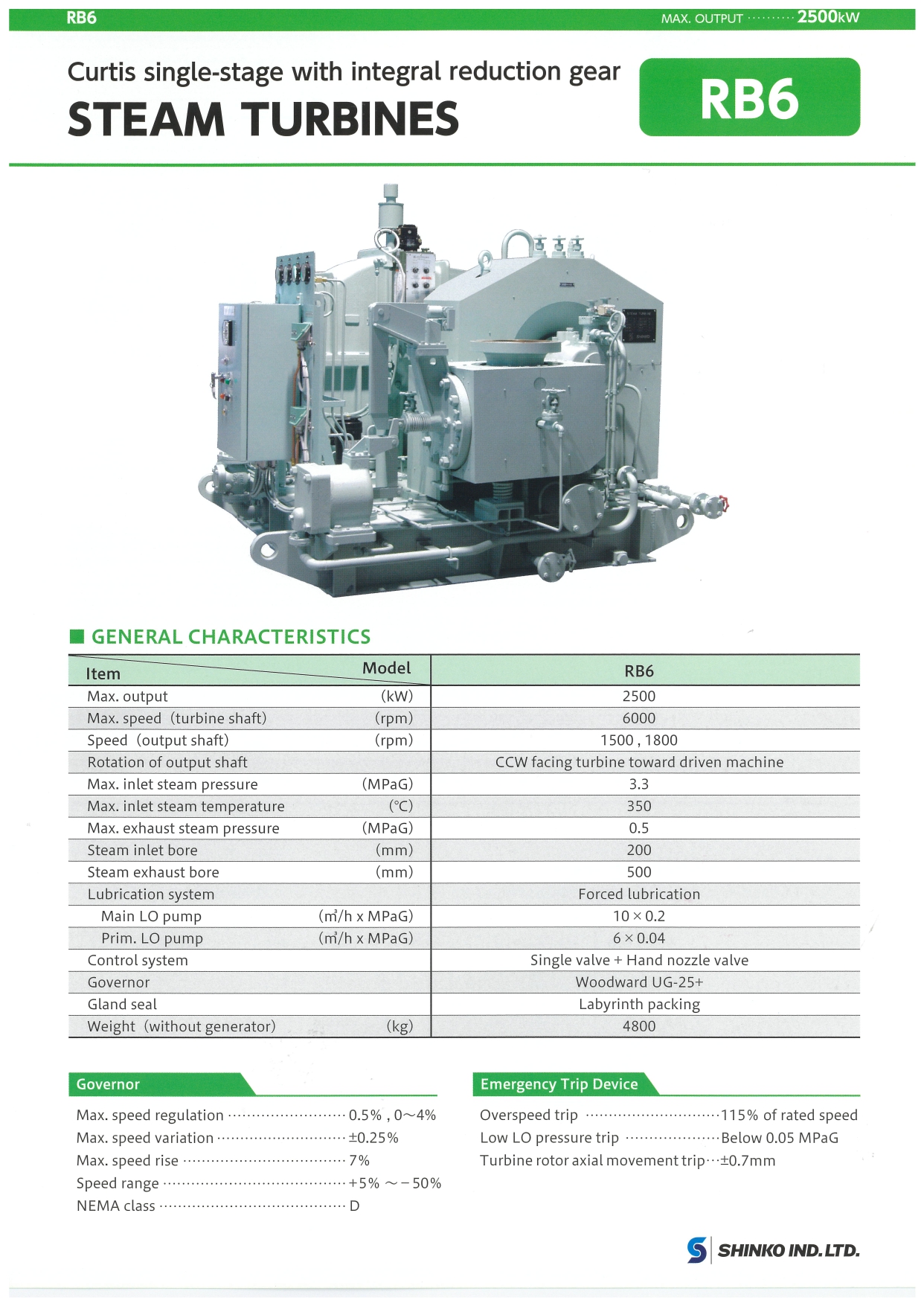

RB6 Curtis Single Stage With Integral Reduction Gear

SPECIFICATION

Above 2000kWe upto 2,500kWe at Alternator Output

Turbine Inlet Steam Pressure : Up to 30barG

Turbine Inlet Steam Temperature : Up to 300°C (*330°C)

Turbine Exhaust Steam Pressure : Up to 5barG

*Case-to-case basis

Description

SPECIAL ADVANTAGE FEATURES

Trip and throttle (T&T) valve have advantage of:

- Less valve stem jam problem.

- Lower steam pressure drops across the governor valve.

Steam ejector to extract gland leakage steam from packing gland to avoid leakage steam get into oil sump and contaminate the lubrication oil.

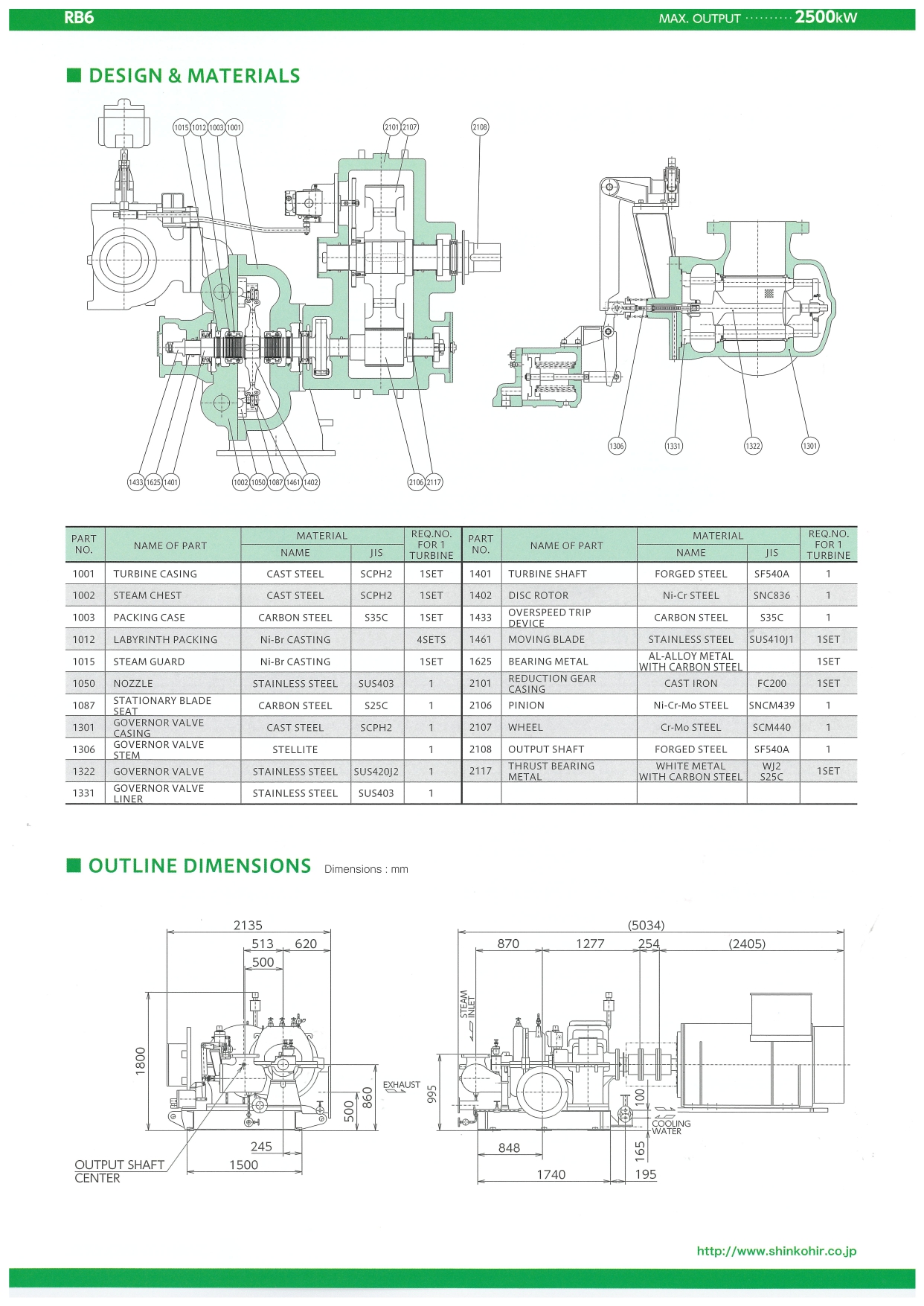

Turbine shaft is sealed by labyrinth packing which is more efficient and durable as compared to carbon rings. The latter need to be replaced on each turbine service.

Lubrication oil strainer is cleanable type without disposable filter element, thus more economical and environmentally friendly.

Turbine shaft is installed with axial movement sensor, an extra protection feature, to trip the turbine due to excessive axial movement caused by excessive thrust created by wet steam or water carry over.

Maintenance free flexi disc pack coupling is used instead of gear teeth coupling. Gear teeth coupling worn off easily and needs regular maintenance and frequent replacement.

Turbine is of in between bearing design with integral speed reducer supported by two bearings.

Shinko steam turbine is fully manufactured, assembled and tested with life steam Shinko factory before shipment. This will ensure that the Shinko steam turbine is aligned and assembled properly, thus avoiding vibration and misalignment problems at site.

Additional Info

*NEW Optional* Turbine Control Panel with Parameter Touch Display with Data Logging

- Turbine Rotor Vibration & Axial Movement Monitoring

- Pressure Parameter Display for Inlet Steam, Exhaust Steam, Lubrication & Control Oil

- Temperature Parameter Display for Inlet Steam, Reduction Gearbox Bearings, Turbine Bearings, Generator Windings & Bearings